Based on the Study: Float Life Expectancy of VRLA-Batteries Based on High Temperature Float Tests by Friedrich Kramm (Deutsche EXIDE GmbH)

For decades, the standard method for predicting Valve Regulated Lead Acid (VRLA) battery life has relied on simple extrapolations of temperature and time. However, real-world UPS battery monitoring data often contradicts these predictions, with batteries failing well before their "design life." This paper analyzes the results of a comprehensive six-year study conducted by Exide Technologies regarding the aging behavior of VRLA batteries.

The study reveals a critical discrepancy: VRLA battery aging behaves completely differently depending on whether the battery is discharged slowly (telecom style) or quickly (UPS style). This paper breaks down the study’s findings on AGM versus Gel technologies, the impact of temperature on high-rate discharge, and the irrelevance of humidity, providing actionable insights for improving battery monitoring strategies and system reliability.

1. Introduction: The Design Life Myth: Why "Healthy" UPS Batteries Fail Without Warning

Every facility manager knows the sinking feeling of a battery string failing a load test years before its warranty or design life suggests it should. In the world of Uninterruptible Power Supply (UPS) systems, reliability is the only metric that matters.

Traditionally, manufacturers have calculated "design life" using high-temperature float tests at low discharge rates (typically 10-hour or 8-hour rates). They then extrapolate this data down to standard ambient temperatures (20°C or 25°C) using the Arrhenius Equation. This rule of thumb generally states that for every 10°C (18°F) increase in operating temperature, battery life is cut in half.

While this model works reasonably well for "energy" applications (long, slow discharges like in telecom), this study highlights that it is dangerously inaccurate for "power" applications (short, high-rate discharges like in data center UPSs).

This paper summarizes empirical data collected between 2000 and 2006 on varying battery sizes (12V blocks to 2V cells) and technologies (AGM and Gel). The goal is to provide technicians and managers with a more accurate reality of how their batteries age, specifically when subjected to the high-current demands of modern infrastructure.

2. Background: Technologies and Testing Parameters

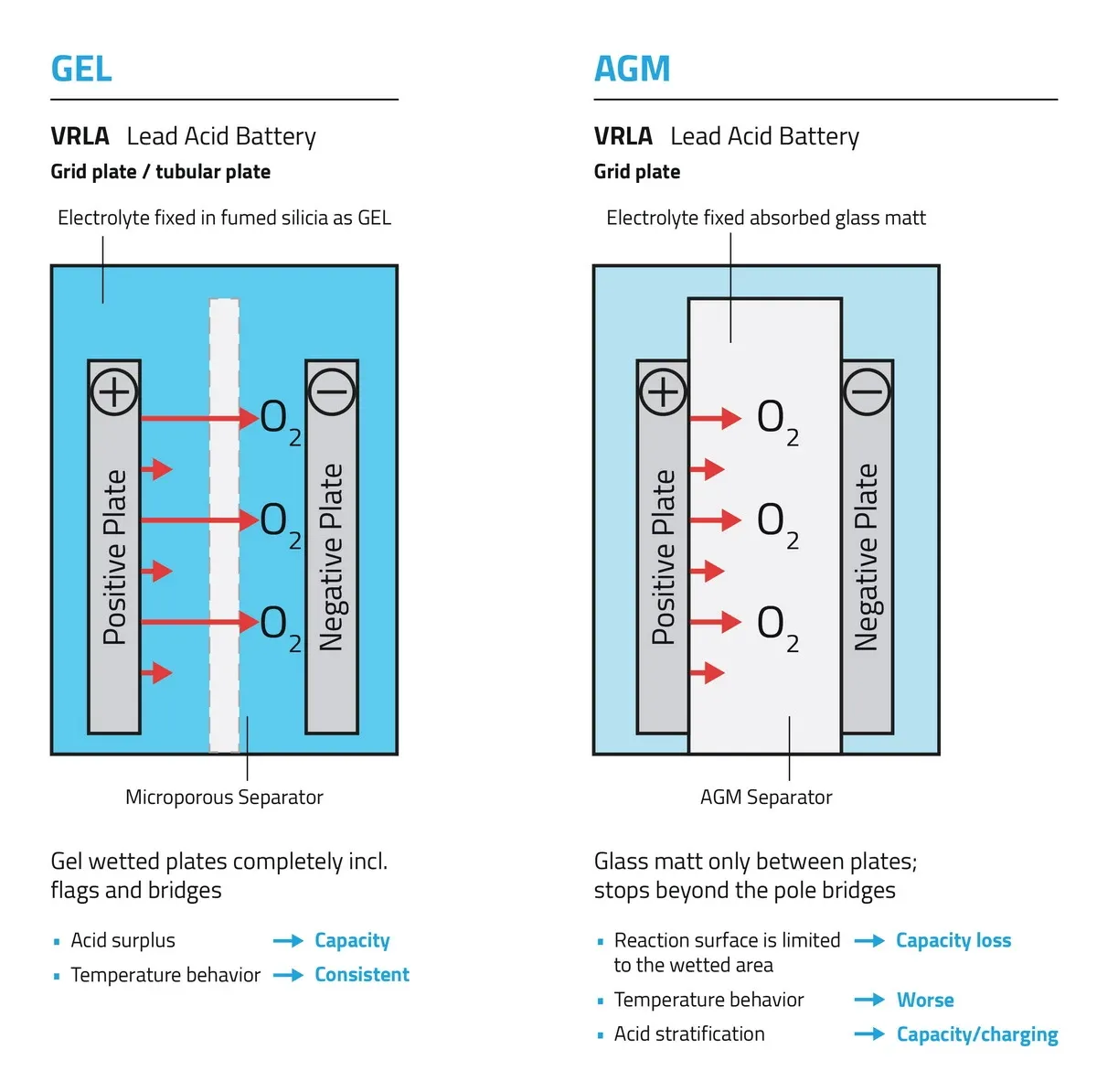

To understand the study's conclusions, and improve your battery maintenance or monitoring, program we must first define the technologies and parameters tested. The study compared the two dominant forms of VRLA batteries found in our facilities:

- Absorbent Glass Mat (AGM): The electrolyte is held in fiberglass mats between plates. These are standard in most UPS applications due to their lower initial cost and high power density. 2.** Gel (Gelled Electrolyte)**: Silica dust is added to the electrolyte to form a thick putty-like gel. These are often viewed as more robust but less power-dense.

Figure 1: Gel/AGM Comparison

Figure 1: Gel/AGM Comparison

The Test Methodology

The researchers did not rely on theoretical modeling. Instead, they conducted physical float tests at accelerated aging temperatures (45°C, 55°C, and 60°C).

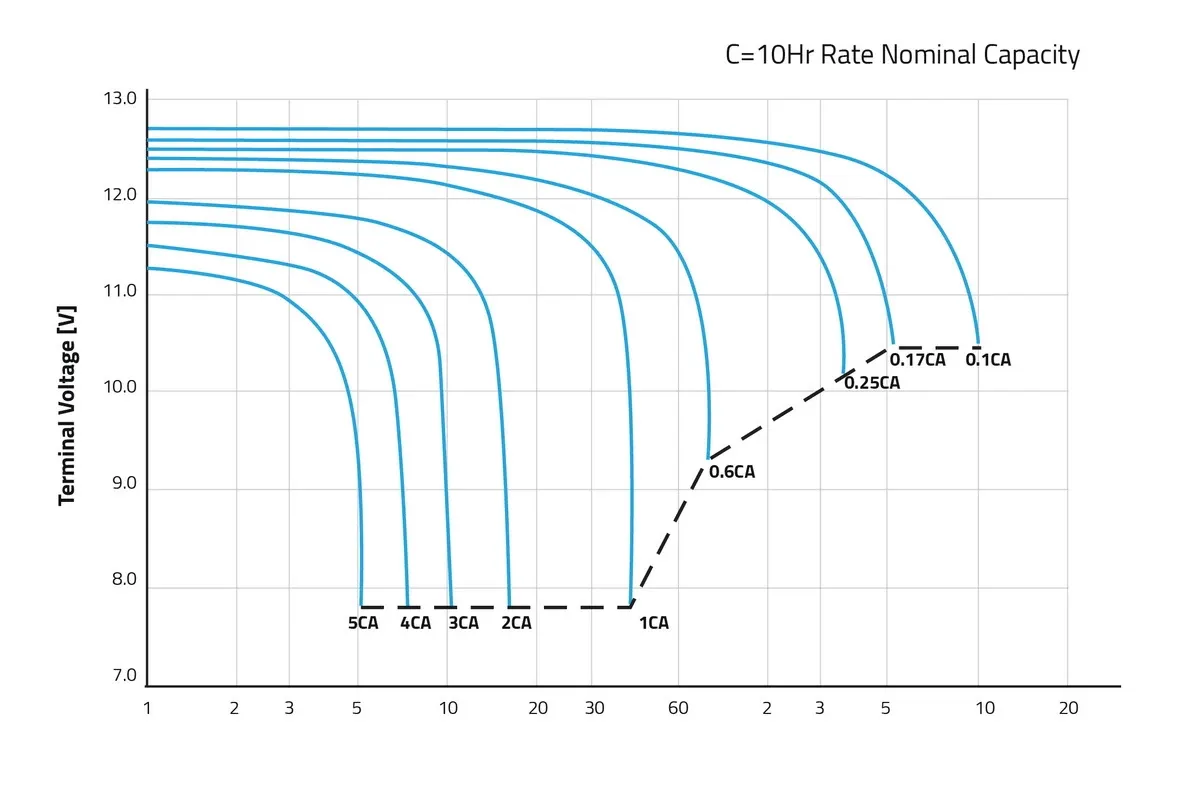

Crucially, they tested Discharge Rates. In battery specifications, "C" represents the capacity.

- Low Rate (C10, C8, C3): Discharging the battery over 3 to 10 hours. This simulates a long outage in a telecom hut.

- High Rate (C1, C0.25, C0.16): Discharging the battery in 1 hour down to 10-15 minutes. This is the critical zone for data center UPSs.

The study sought to determine if a battery that passes a "health check" at a low discharge rate is actually healthy enough to support a high-rate UPS load.

3. Key Finding: The Discharge Rate Discrepancy

The most significant finding of this study is that aging does not affect all performance metrics equally.

When batteries age, their ability to deliver energy (long, slow runtime) degrades much slower than their ability to deliver power (short, high-amperage bursts).

The "Hidden" Failure Mode

The data showed that for both Gel and AGM batteries, the "Low Rate" capacity (e.g., an 8-hour discharge) remained stable for a significant portion of the battery's life. A technician performing a standard low-current capacity test might see the battery sitting at 90-95% capacity and mark it as "Healthy."

However, the High Rate capacity (15-minute discharge) drops off precipitously.

Figure 2: Discharge Rates

Figure 2: Discharge Rates

This chart illustrates the physics of discharge rates. The steep curves on the left (3CA, 1CA) represent "High Rate" UPS loads. The study reveals that a battery's ability to hold these steep curves degrades much faster than its ability to hold the long, slow curves (0.1CA) on the right.

- AGM Batteries: The study revealed a gap between low-rate and high-rate performance that exists from the very beginning. As the battery ages, this gap widens drastically. By the time an AGM battery reaches its "end of life," its ability to support a 15-minute load has degraded significantly more than its ability to support an 8-hour load.

- The Trap: If you are managing a UPS and relying on capacity tests that don't push the battery to high currents, you are likely overestimating your runtime. Your battery might hold voltage for 3 hours at 5 Amps, but collapse instantly under a 200 Amp load.

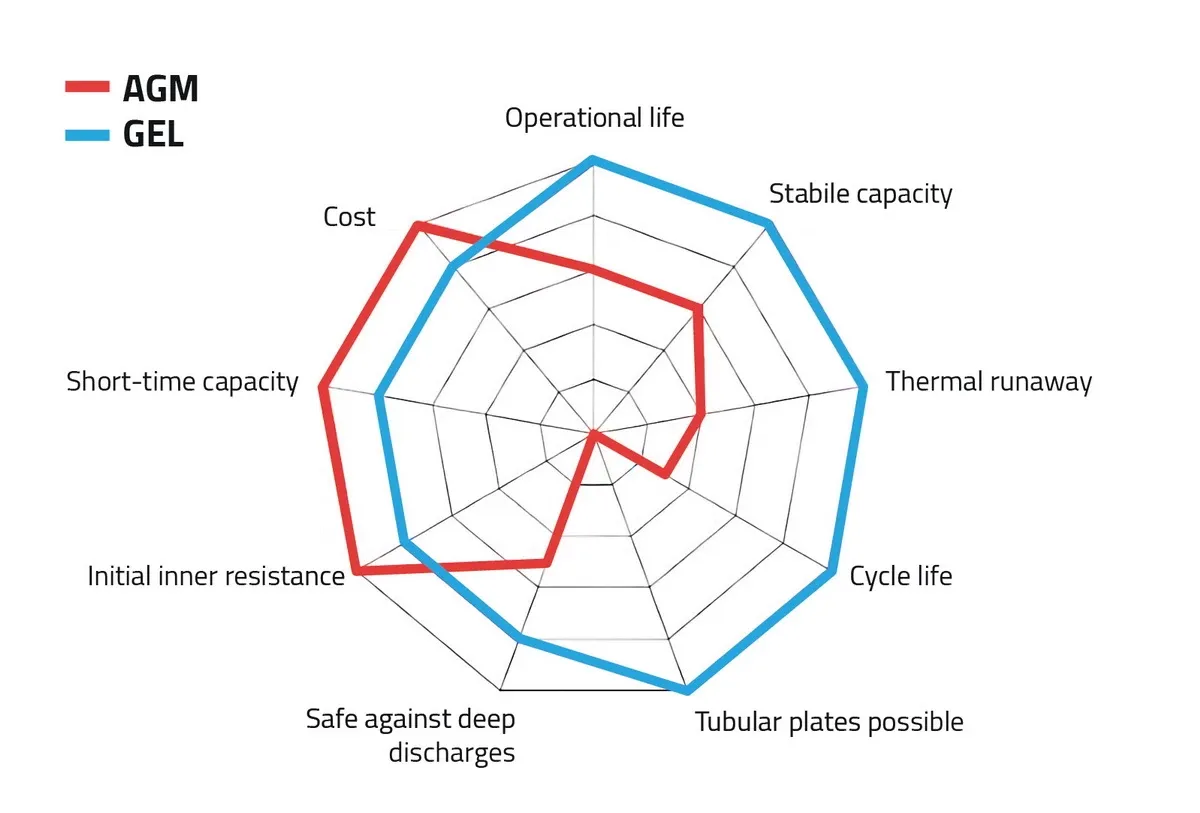

4. Technology Comparison: AGM vs. Gel

For facility managers deciding on their next battery refresh, the comparison between AGM and Gel performance in this study is eye-opening.

The AGM "High Performance" Myth

AGM batteries are often marketed as "High Performance" or "High Power" units. While they do deliver excellent short-duration power when brand new, the study shows they lack longevity in this specific metric.

- Initial Gap: Even when new, the study noted a 10% performance gap between high-rate and low-rate efficiency in AGM blocks.

- Rapid Decline: As the test progressed, this gap widened to over 30%. The "High Performance" design of AGM batteries appears to be more sensitive to aging. The very design features that allow for high current (thin plates, high surface area) degrade faster under float charge conditions.

The Robustness of Gel

Contrarily, the Gel batteries tested (specifically those with robust designs like tubular plates) showed a much higher resistance to this divergence.

- Stability: Gel batteries demonstrated a much flatter aging curve. Their ability to deliver high current did not degrade nearly as fast as the AGM counterparts relative to their lowrate capacity.

- Predictability: The ratio of high-rate to low-rate capacity remained tighter throughout the life of the Gel batteries.

Summary Visual:

Figure 3: Summary Visual

Figure 3: Summary Visual

Technical Takeaway: While AGM might look better on a datasheet for "Watts per Cell" on Day 1, Gel batteries maintain their rated performance more consistently over the lifespan, especially in high-temperature environments.

5. The Impact of Temperature on UPS Applications

We all know heat kills batteries. However, this study refines that knowledge: Heat kills "Power" faster than it kills "Energy."

The tests were conducted at elevated temperatures (55°C and 60°C) to accelerate aging. The results indicated that high temperatures have a specific, negative impact on high-rate discharge performance that is more severe than the impact on low-rate performance.

The Multiplier Effect

For the AGM batteries tested:

- Comparing 45°C to 55°C, the high-rate capacity (C0.25) dropped by an additional 12% over the life of the test.

- This suggests that the "Arrhenius Equation" (the 50% life reduction rule) is actually optimistic when applied to UPS batteries. The chemical activation energy required for high-current discharge is more sensitive to thermal degradation.

Figure 4: Thermal View

Figure 4: Thermal View

Implication for Cooling: If your battery room has hot spots, the batteries in those areas aren't just losing overall life; they are specifically losing the ability to support your UPS load during a power spike. This is why ambient and cell level temperature monitoring is so important — it identifies hot spots that degrade system reliability.

6. The Humidity Myth

A brief but valuable sidebar in the study investigated the impact of humidity. Tests compared batteries floating in 10% relative humidity versus 35% relative humidity (standard IEC condition).

The Result: No significant impact. The ratio of capacity retention was virtually identical.

Operational value: While you should monitor humidity for static electricity, you do not need to worry that dry air is drying out your VRLA batteries through the plastic casing. The internal recombination efficiency and valve sealing are the primary factors in water loss, not ambient humidity.

7. Practical Implications for Facility Managers & Battery Monitoring Programs

Based on the data presented in this study, we can draw several conclusions that directly affect facility maintenance and procurement strategies, and monitoring programs.

A. Re-evaluating Design Life

The term "10-year Design Life" on a brochure is calculated based on low-rate discharges. If you are running a Data Center UPS:

- Discount the Rating: A "10-year" AGM battery in a high-rate application should likely be treated as a 5-7 year asset for reliability purposes.

- Separate Metrics: We must stop treating "Battery Health" as a single number. A battery has "Energy Health" (Amp-hours) and "Power Health" (Watts-per-cell). You need to test for the latter.

B. Testing & Monitoring Protocols

If your service provider is performing conductance or resistance testing or you are continuously monitoring those parameters, that is a good start for trending. However, if they perform a load bank test:

- Demand High Rate Testing: You need to test the batteries at a rate that simulates your actual critical load (e.g., a 15-minute rate).

- Watch the Voltage Drop: Aging manifests as a deeper voltage sag under high load.

8. Summary of Recommendations

To apply this technical study to your facility management roadmap:

- Shift to High-Rate Testing: When load testing, ensure the rate mimics your actual UPS runtime (5-30 mins), not just generic capacity tests.

- Temperature Control is Critical for Power: Recognize that even minor temperature elevations degrade the peak power output of your batteries faster than their overall capacity. Monitoring gives you visibility on a cell or jar level over hotspots or imbalances in battery temperature. This visibility allows you to implement and validate tighter cooling tolerances to yield better UPS reliability.

- Procurement Strategy: When creating RFPs for battery replacements, ask vendors for aging curves specifically for high-rate discharges. Do not settle for the standard "C10" (10-hour) discharge curve.

Conclusion

The Exide study shows "a battery is not just a battery." The divergence between low-rate and high-rate aging means that facility managers may be sitting on a false sense of security. By understanding that UPS applications stress batteries in a way that standard "Design Life" calculations ignore, we can adjust our testing, monitoring/maintenance, and purchasing habits to ensure that when the utility power cuts, the batteries actually show up to work.

References:

F. Kramm, "Float Life Expectancy of VRLA-Batteries Based on High Temperature Float Tests Impact of Discharge Rate, Design and Test Parameter," in INTELEC 06 - Twenty-Eighth International Telecommunications Energy Conference, Providence, RI, USA, 2006, pp. 1-5.